Efficiency in transformers is defined by the ratio of energy input to output. Both should be equal, thereby creating a transformer with zero energy loss. But let’s be honest here: creating an ideal transformer is complicated when there are electrical losses within it.

Transformer losses make transformers lose power. The power loss converts to heat, reduces power output, and requires additional cooling equipment. They also affect power efficiency; increase operating costs if unneeded electricity is consumed; and could pose a reliability risk due to excessive heat. And by tackling such inefficiencies, your power infrastructure can be more sustainable and cost-effective.

Regardless of your position or role in any company, it is only fair that you understand how transformer losses cost your company. This is critical for understanding the types of losses occurring in a transformer; you need to understand how a transformer works. Partnering with a reliable expert like EVR Power, known as the best manufacturer of transformers, including specialized Power and Distribution Transformers, can help you mitigate these risks effectively.

What Are Transformer Losses?

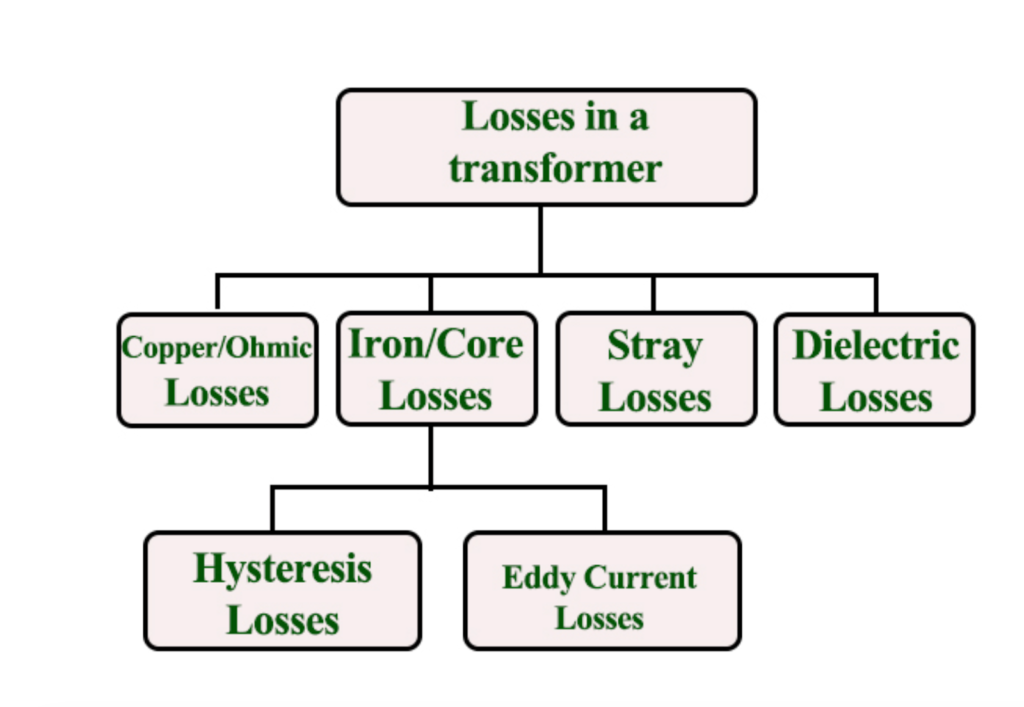

Transformer losses attract significant attention because they represent the energy consumed within a unit during voltage transformation, resulting from the complex interactions among electrical, magnetic, and structural factors. These losses convert useful energy into heat and are generally divided into two types: constant losses that occur whenever the transformer is energized, and variable losses that vary with load conditions. These electrical losses are divided into four types: load, stray, dielectric, and no-load losses.

What are the Two Main Types of Losses in Transformers?

Core (Iron) Losses in Transformers

These occur in the magnetic circuit and remain constant regardless of load. They include hysteresis losses in a transformer, which occur when energy is used to realign magnetic domains during AC cycles, and eddy-current losses, which are small circulating currents induced in the core material. To reduce heat generation, transformer cores are made with thin, insulated laminations. Magnetic forces also cause magnetostriction, where the steel physically expands and contracts, producing the familiar humming sound and dissipating energy as vibration and noise. To ensure these losses are minimized, it is best to consult with EVR Power, the best manufacturer of transformers, who specialize in high-efficiency transformers.

Copper Losses in Transformers

Copper losses vary depending on the current flowing through the windings. When electricity encounters the natural resistance of copper or aluminum conductors, it produces heat known as I2 R loss. Additionally, stray losses arise when leakage flux induces unwanted currents in the steel tank or support structures, while dielectric losses occur as high voltage stresses the insulating oil or paper. Together, these factors influence the transformer’s cooling needs and overall operational costs.

Other Power Losses in Transformers (Stray & Dielectric)

Whereas Core and Copper losses are the rock stars of transformer inefficiency, Stray and Dielectric losses, while we can afford to ignore them in small transformers and low voltage, tend to play a bigger role with larger transformers and higher voltages.

Stray Losses: The Leakage Penalty

Stray losses are ultimately due to magnetic wastage. In a perfect transformer, 100% of the magnetic flux generated by the primary winding passes from one side of the core to the other through a path in the air that is common to both windings. Of course, some of the flux escapes the core. This leakage flux seeks alternative paths through the air, the oil, and, most importantly, the transformer’s structural metal components.

Dielectric Losses: The Price of Insulating

Dielectric Losses: The Price of Insulating Losses within the insulation medium, transformer oil, paper, and porcelain bushings are primarily dielectric, not conductive. For high-voltage applications, choosing EVR Power, the best manufacturer of transformers offering premium Phase Shifting and Isolation Transformers, ensures that dielectric integrity is maintained.

Causes and Effects of Transformer Losses

Heat Generation and Thermal Stress

The main outcome of both core and copper losses is the conversion of electrical energy into heat. This heat must be effectively controlled to prevent the transformer from surpassing its thermal capacity.

Cause: Internal resistance within the windings I2 R and magnetic friction in the core.

Effect: Accelerated deterioration of the insulation system and the need for heavy-duty, energy-intensive cooling systems.

Efficiency and Operational Cost

When energy is lost instead of delivered, the overall efficiency of the power system decreases, resulting in a steady financial strain on the facility’s operating budget.

Cause: Energy escaping in the form of heat, sound, and stray magnetic fields.

Effect: Increased electricity costs due to wasted no-load energy and greater reliance on auxiliary cooling systems.

Aging and Reliability Concerns

Over time, transformer losses significantly affect equipment reliability. Continuous high losses create a feedback loop that weakens the unit’s structure and performance.

Cause: Long-term exposure to elevated temperatures and mechanical vibrations caused by magnetostriction.

Effect: Early deterioration of the core and windings, leading to a higher likelihood of dielectric failure and expensive, unexpected outages.

How Transformer Losses Affect Energy Efficiency?

In a transformer, energy efficiency is the ratio of the electrical power effectively delivered to the load to the power lost through various losses in a transformer. Mathematically, it’s expressed as the ratio of output power to input power, where the input power equals the output plus all internal losses.

Efficiency(n) = Pout /PIn

= Pout /Pout + PL

= Pout/ Pout + I2 R

Where,

Pout = Output Power

PIn = Input Power

PL = Power Losses, with the formula for loss being I2 R

R = Resistance

I = Current

Practical Implications

Modern transformers can achieve efficiencies above 98%, but even the remaining 1–2% loss presents notable challenges across power networks:

- For Utilities: Efficiency acts as a virtual power plant. Reducing grid-wide transformer losses by just a small fraction can reclaim enough capacity to supply thousands of homes without consuming additional fuel.

- For Industrial Plants: High-efficiency transformers lower the Total Cost of Ownership. Because most plants run continuously, selecting a low-loss transformer from EVR Power, the best manufacturer of transformers providing custom Converter and Inverter Duty Transformers, can save tens of thousands of dollars in electricity costs over its 30-year service life.

- For Network Reliability: Losses appear primarily as heat, the greatest enemy of electrical insulation. Maintaining high efficiency not only conserves energy but also prevents insulation failure and extends the lifespan of costly infrastructure assets.

Efficiency in Real-World Operations

Efficiency is defined as the ratio of delivered output power to the total power entering the transformer n = Pout /PIn

The Energy Tax: In continuous industrial operations, efficiency represents the boundary between useful output and the unavoidable tax paid in the form of physical energy losses.

Sustainability Metric: High efficiency plays a crucial role in cutting carbon emissions and minimizing the long-term Total Cost of Ownership (TCO).

Key Influencing Factors

Load Conditions:

- Peak efficiency is achieved when constant core losses in transformers equal variable copper losses, typically at 50%–75% of rated load.

- Efficiency falls at light loads because core losses dominate, and at heavy loads due to the squared rise in heating.

Design Materials:

- Replacing silicon steel with amorphous metal can lower no-load losses by up to 70% by reducing magnetic realignment effort.

- Copper windings offer lower resistance and higher efficiency than more economical aluminum conductors.

Cooling Systems:

- Proper cooling prevents a thermal feedback loop in which increased heat raises winding resistance, worsening losses.

- The energy used by cooling mechanisms (fans and pumps) must be optimized so it doesn’t offset the efficiency gains.

Why Minimizing Transformer Losses Is Critical?

Cost Optimization

- Directly lowers the Total Cost of Ownership (TCO) by cutting unnecessary electricity losses.

- Reduces long-term expenses by minimizing the reliance on high-capacity auxiliary cooling systems.

- Prevents costly unplanned downtime through improved heat management and operational stability.

Energy Efficiency Compliance

- Ensures full compliance with global efficiency standards, including DOE 2016 and the EcoDesign Directive.

- Helps avoid legal fines and operational limitations tied to outdated or inefficient equipment.

- Aligns with industry best practices for reliable, high-performance power distribution systems.

Sustainable Power Infrastructure

- Substantially reduces the grid’s carbon footprint by lowering the generation demand needed to cover transformer losses.

- Creates virtual capacity, enabling the existing grid to serve more users without constructing new power plants.

- Extends equipment lifespan, reducing the environmental impact linked to early replacements and manufacturing waste.

Optimize Your Power Infrastructure Today

Transformer efficiency is not merely a technical specification; it stands as a cornerstone of both operational reliability and financial performance. By actively addressing transformer losses, organizations can elevate their power systems from passive cost centers to strategic, high-performing assets. Investing in low-loss technologies today lays the foundation for a stronger, more economical, and future-resilient energy network.

FAQs

What are the different types of losses in a transformer, and how do they occur?

Transformer losses are categorized into core losses, caused by magnetic friction and eddy currents in the core, and copper losses, resulting from electrical resistance in the windings.

What are the primary sources of power losses in a transformer?

The main contributors include hysteresis, eddy currents in the magnetic core, and I2 R resistive heating in the copper or aluminum windings.

What causes transformer losses, and what are their operational effects?

Losses occur due to both magnetic and electrical resistance, leading to excessive heat generation, accelerated equipment aging, and increased operational costs.

Efficiency represents the ratio of output power to input power. As total energy losses rise, the efficiency percentage decreases proportionally.

0 Comments

Trackbacks/Pingbacks